Galvanic Isolator Gi50/32/S/SA (Purchased after 24 April 2017)

Galvanic Isolator Instructions

Gi50/32/S/SA – Surge Current 120A

The Gi50/32/S/SA Galvanic Isolator is intended to prevent galvanic and stray currents from finding a circulating path through the earthing connection of a shore supply. It does this by breaking the earth connection from the perspective of Galvanic/Stray currents, while ensuring an uninterrupted path to earth for fault currents. Thus the integrity of the safety electrical earth is maintained.

The Gi50/32/S/SA Galvanic Isolator is intended to prevent galvanic and stray currents from finding a circulating path through the earthing connection of a shore supply. It does this by breaking the earth connection from the perspective of Galvanic/Stray currents, while ensuring an uninterrupted path to earth for fault currents. Thus the integrity of the safety electrical earth is maintained.

Inside the box you should have:

- 1 x Galvanic Isolator

- 1 x Display

- 1 x Connecting Cable (attached to display)

- 4 x lengths of heat shrink tubing (or 1 long length)

Please read through these instructions. If you are not confident that you can fit this item yourself, please consult a qualified electrician or call us to exchange the unit for our plug in isolator of similar rating, which is “plug & play”, requiring no installation.

Siting the unit:

The main and display units are designed for internal use, and should be located in a dry place where they will not be subject to excessive heat or physical damage. In most cases the main isolator will be located near to the point where the mains supply enters the vessel.

nbsp;

The Remote Indicator can be placed up to 100 feet (30m) away from the main unit.

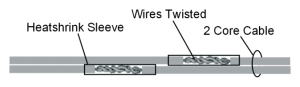

If it is desired to lengthen the connecting cable, we recommend that you use a multi stranded cable of similar type to that fitted. The cable may be lengthened or shortened by cutting the cable, and re-joining it.

Strip the ends by about 1cm, twist the wires tightly together, then insulate using the heat shrink tubing supplied. Offset the joints of the two cores by about 3 centimetres, as shown in the image. Ideally the joint should be soldered, but twisting tightly is normally sufficient.

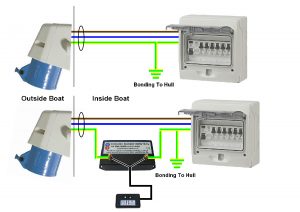

To comply with CE standards, the earth connection of your boat must be bonded

electrically to the hull. This is a requirement of the Recreational Craft Directive, and essential for the electrical safety of the boat.

1) Disconnect the boat from the shore supply, and ensure that any invertors/generators etc are switched off. Please refer to the “before & after” diagram below.

2) Disassemble the power input connection attached to the boat, and locate the EARTH terminal. This will normally have a green or green/yellow cable connected to it. It is the LONGEST pin in the connector.

3) Disconnect that cable, and route it inside the boat to the place where the isolator will be located.

(If there are several wires in the terminal, they must ALL be routed to the same place and connected to the same terminal of the isolator. This is CRUCIAL to ensure that the earth bonding is retained, and that your isolator works as intended). Label the cable(s) so that they can be identified later.

4) Connect a new cable from the earth terminal of the power input connection, and route it inside the boat to the place where the isolator will be located. This cable should have a cross sectional area of at least 2.5mm2 . Label the cable so it can be identified later.

5) Having fixed the isolator, connect the single cable to one of the terminals on the isolator (either terminal can be used).

6) Connect the remaining cable(s) to the other terminal of the isolator. Do not tighten yet.

7) Reassemble the power input connection, ensuring that all screws are tight.

8) Decide on a location for the Remote Indicator. This can be up to 100 ft (30m) from the Isolator.

9) It is suggested that you first position the Remote Indicator, and then route the cable back to the Isolator.

The cable connecting the Isolator and the Remote Indicator must be insulated throughout it’s length. It must not be connected to anything else under any circumstances.

10) Connect the terminals on the end of the Remote Indicator connecting cable to the stud terminals on the Isolator.

11) You should now tighten the connections to the isolator, taking care not to over tighten.

13) The power may now be reconnected.

14) If any of the lights illuminate, earth leakage is present. It is NOT a sign of a faulty isolator! Please refer to the fault finding information below.

Galvanic Isolator Gi50/32/S/SA

Operating Instructions

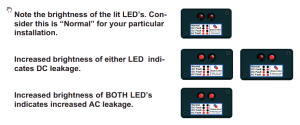

The LED’s on your isolator inform you of any faults with your boats Earthing arrangement.

Illuminated LED’s NEVER indicate a faulty isolator.

IDEALLY, the lights will be as in the picture. Please click on the image to enlarge.

Occasionally, when a Status Monitored galvanic isolator is fitted, both of the warning lights may glow straight away.

If both lights are illuminated on your galvanic isolator, you have AC earth leakage. You do NOT have a faulty isolator.

In fact, your isolator is alerting you to a potentially dangerous situation that you may not previously have been aware of.

There are two main types of earth leakage: Mains Leakage and Imprinted Leakage.

Mains Leakage

Mains Leakage happens when an appliance, cable or connection has poor insulation resistance, and some of the circuit’s current “leaks” away to earth. If there is sufficient leakage, the earth leakage circuit breaker, also known as the RCD, will trip, disconnecting the supply.

At lower levels of leakage, the RCD may not trip, but the lights on your galvanic isolator may still glow, alerting you to the likelihood of earth leakage. Usually, an earth leakage fault will only get worse, so you should always take this seriously and investigate.

No two electrical systems are the same, so it’s only possible to give the broadest suggestions of how to locate any problem. Usually some detective work is required, and this starts by switching off the main RCD on the boat. In most cases, this will result in the lights going out. If not, there is probably something connected to the mains supply BEFORE the RCD.

Assuming the lights go out when the RCD is switched off, switch off ALL the circuit bbreakers, then switch the RCD back on. In most cases, the isolator’s lights will stay off. You can then switch the circuit breakers back on one at a time until the isolators lights come back on. The last circuit breaker you switched on has the faulty circuit, or appliance connected to it.

Very rarely, even though all the circuit breakers (except the RCD) are switched off, the isolator lights will remain on. In this case you will need to disconnect all appliances, either by pulling out the plugs, or disconnecting any wired in appliances. Do this one at a time, taking care to ensure that you don’t forget anything. As you disconnect items, check the isolator lights. The last item you disconnect is the one causing problems.

Very rarely, even though all the circuit breakers (except the RCD) are switched off, the isolator lights will remain on. In this case you will need to disconnect all appliances, either by pulling out the plugs, or disconnecting any wired in appliances. Do this one at a time, taking care to ensure that you don’t forget anything. As you disconnect items, check the isolator lights. The last item you disconnect is the one causing problems.

When you have traced the fault to a single appliance or circuit, it must then be checked for earth leakage by a competent person.

Imprinted Earth Leakage

Imprinted Leakage typically occurs when equipment using a Switched Mode Power Supply Unit, (SMPSU), is connected to your system.

Equipment utilising SMPSU’s include, Battery Chargers, Computers, TV’s, Domestic Appliances, Phone Chargers etc.

In our experience, battery chargers are often the cause of imprinted leakage. CE regulations require that equipment should not create this kind of interference, but not all equipment is as “clean” as it should be.

In our experience, battery chargers are often the cause of imprinted leakage. CE regulations require that equipment should not create this kind of interference, but not all equipment is as “clean” as it should be.

Because of the way SMPSU’s operate, some of them leak power into the boat’s earth wiring. This can cause the galvanic isolators light to come on, as the isolator correctly detects the leakage.

Imprinted Leakage is traced in exactly the same way as for Mains Leakage. However, when you track the problem down to an individual appliance, it may still pass an Earth Leakage test. In that case, it’s likely that the problem is Imprinted Leakage. Imprinted Leakage is often due to incorrect installation, but can also result from design or manufacturing issues.

Usually, Imprinted Leakage won’t significantly degrade the performance of your isolator, and provided it is confirmed that no Mains Leakage is present, the appliance may continue to be used.

In the presence of Imprinted Leakage, you should now read the fault indicator lights as in the picture above. Please click on the image to enlarge.

Your Gi50/32/S/SA has been designed to give many years of service, and is covered by a 5 year guarantee against faulty workmanship or parts. In the event of a major electrical fault, lightning strike etc, we recommend that your isolator is checked to confirm correct operation. We offer a free checking facility. If you wish to take advantage of the service, please email or phone us for a returns number.

Galvanic Isolator Fault Diagnosis Flowchart