If you spend time in a marina, give a thought to your boat and her hull.

When your boat is moored and connected to an electric hookup, galvanic currents can seriously damage her underwater metalwork, outboard casings, and even the hull. The longer the connection lasts, the more corrosion occurs.

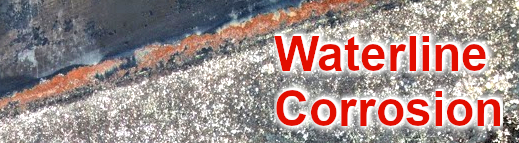

To check for signs of damage, inspect the area around the waterline. Pitting and corrosion often begin here, and galvanic currents are a frequent cause (see the top image).

In the lower image, the silver spots represent zinc from the anodes that have plated this boat's hull due to galvanic currents. This zinc provides some protection for the hull, but the anodes themselves will corrode over time. Once the anodes are completely gone, the hull will no longer have any protection, leading to the formation of deep pits that could eventually perforate the boat's hull.

You can easily prevent this type of corrosion by installing a simple galvanic isolator. There's no need for any wiring—just plug it in, and the galvanic currents will stop instantly.

People have reported that hull pitting ceases and that anodes last several times longer after installing a galvanic isolator.

From our own experience, as narrowboat owners, if you can't "black" your boat's hull as often as you'd like, a galvanic isolator can help extend the time between haul-outs.

In fact, our boat hadn't been "blacked" for four years, and when we finally took her out of the water, we found very little anode use, and the small amount of corrosion that was visible had not worsened at all.

For more information, please <Click HERE>